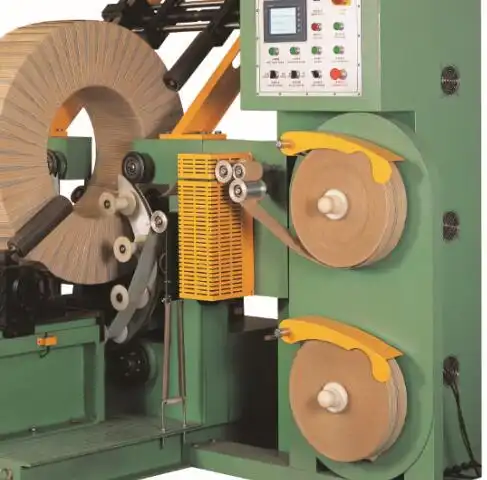

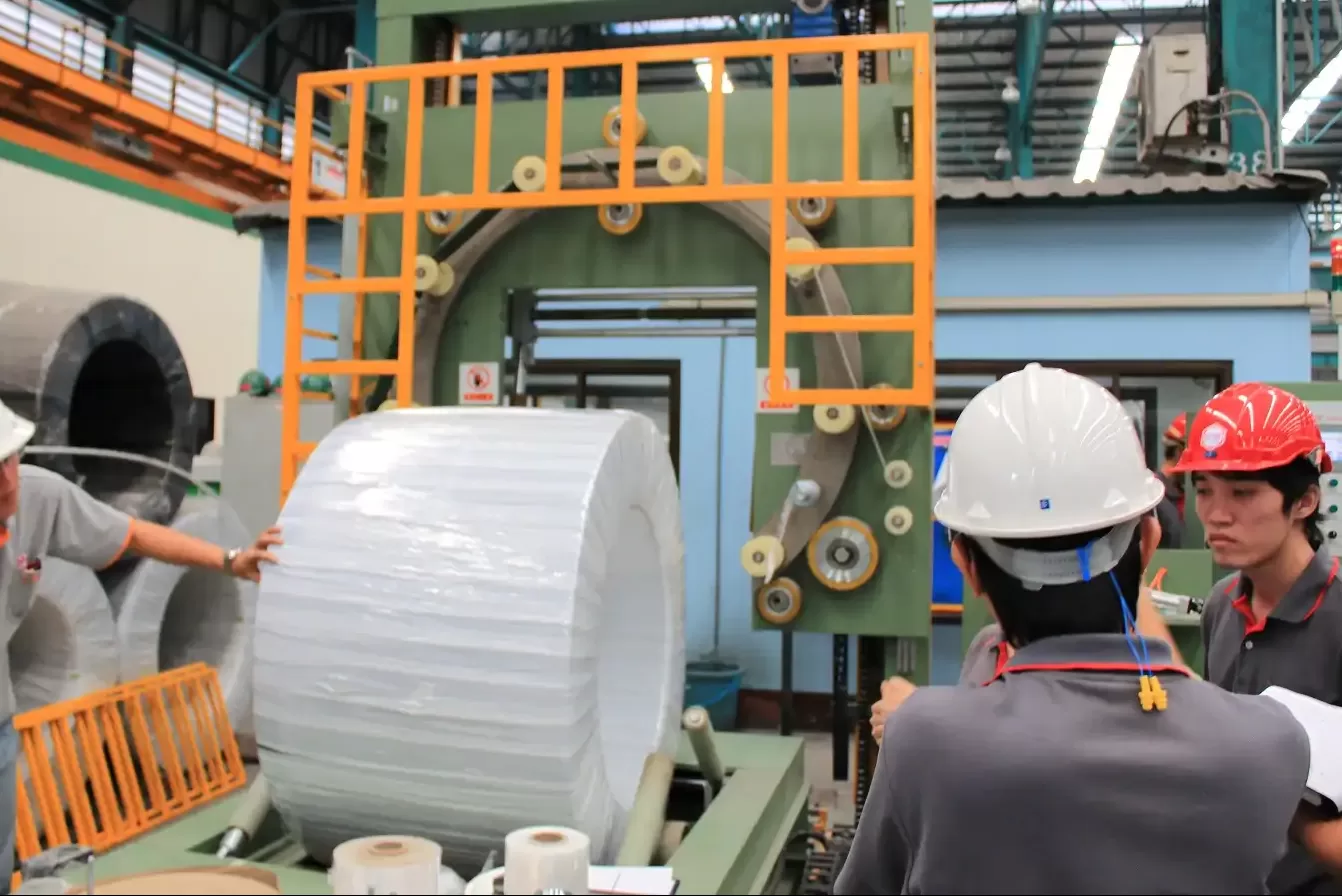

What Should I Consider When Searching for a Reliable Coil Wrapping Machine Manufacturer?

# What Should I Consider When Searching for a Reliable Coil Wrapping Machine Manufacturer? In the world of industrial machinery, […]

What Should I Consider When Searching for a Reliable Coil Wrapping Machine Manufacturer? Read More »